Road studs are used for dividing roads, separating roads or lane arrangement within the scope of traffic and road safety. Usually, there are reflective material or reflector on road studs. The reflectors (known as cat eyes) are small but important material acts as a light by reflecting the vehicle headlights. Reflectors are used in three ways: Reflective sheet, plastic reflector, glass bead. Glass beads have the longest life span and reflective sheets have the shortest life span among those reflector types. Usually, plastic reflectors and reflective sheets are preferred in temporary road maintenance works. Using glass beads would be beneficial in permanent places or the places where it is expected to last longer.

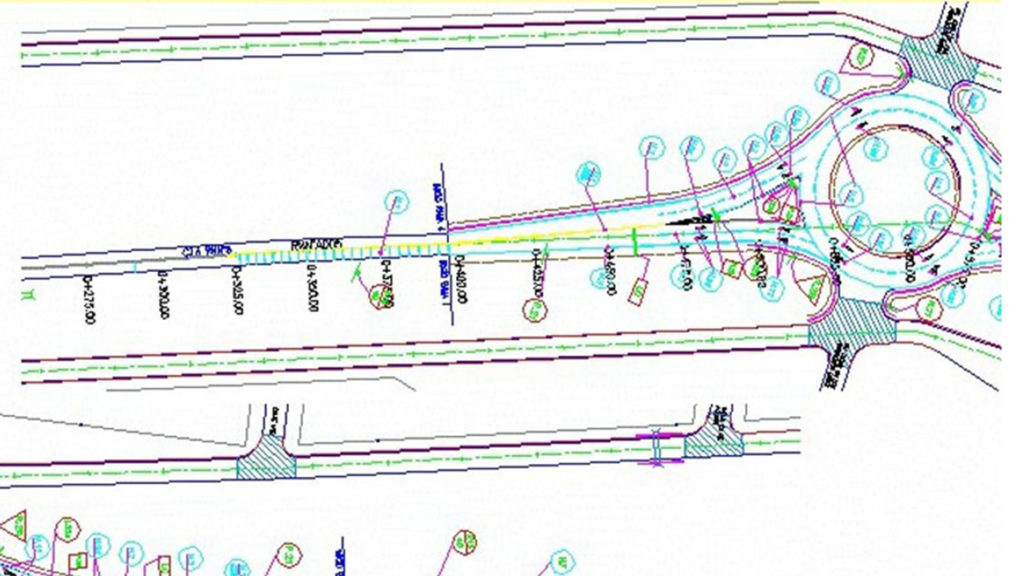

Those reflectors are installed on plastic or aluminum housings. Road studs which consist of housing and reflector are mounted on road or related place with screw and fixing plug. Road studs with rods are mounted on roads with stud method and fixed to the ground with epoxy-style adhesives. The size of the related road stud is decided according to the area of usage. Especially, deciding of height is very important for the use of road stud. Will it be used to lower the speed? or will it be used for lane arrangement?

So, what are the differences between plastic or aluminum road studs?

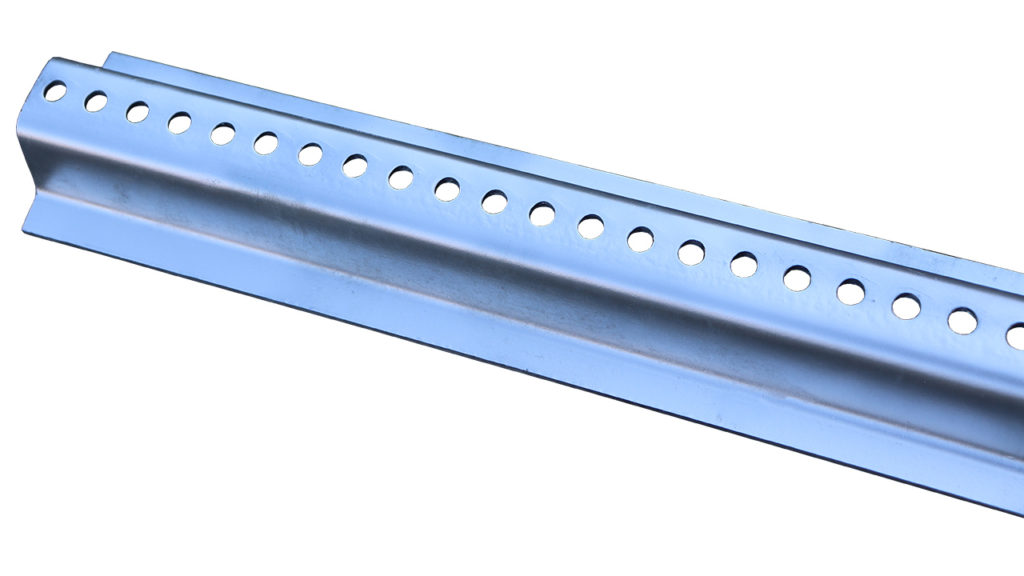

• Aluminum road studs are more durable and have a longer life span than plastic road studs.

• The price of aluminum raw material is higher than the plastic one in terms of the purchase cost. Therefore, aluminum road stud prices are 40 % expensive than plastic road stud of similar sizes.

• Plastic road studs can be used in temporary or short-term road maintenance works. Aluminum road studs can be used for long term road works or permanent road divider.

• Both plastic and aluminum road studs can be used to determine the boundaries of right and the left side of the road. Aluminum road stud is recommended if it is applied in the middle of the road for lowering the speed of vehicles and to provide awareness for drivers.

• The compression resistance of plastic road studs is 5-10 tons. But it is 30-40 tons for aluminum road studs. In this way, the selection of road stud type can be changed according to the area of usage.

• Plastic road stud can be applied inside the factories where there is not much traffic flow or vehicle speed, in front of hospitals and schools. Aluminum road studs are recommended on roads where the speed of vehicles are high and where heavy vehicles like trucks are on the road.